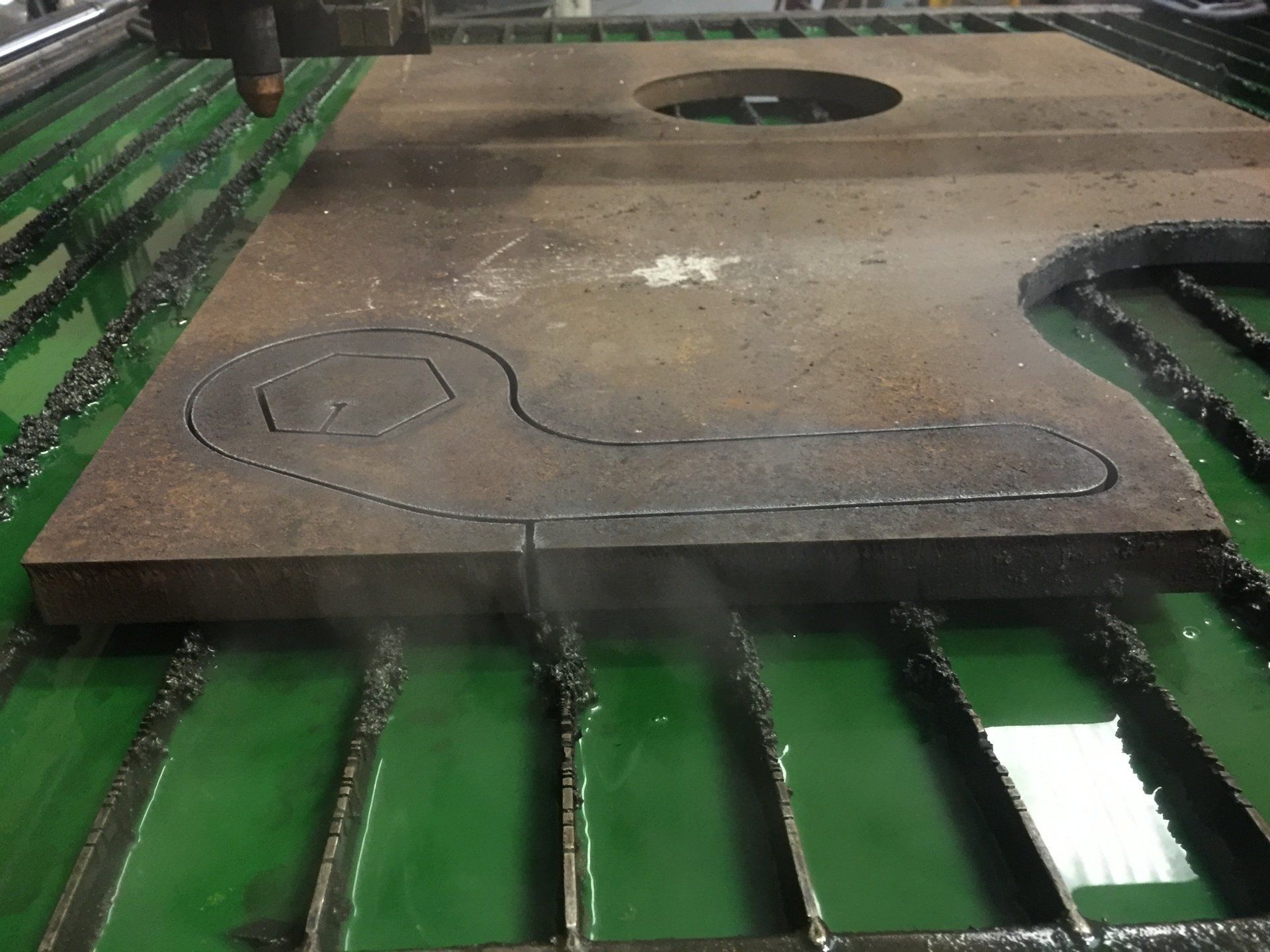

CNC Plasma Cutting

CNC Plasma Cutting Services

At PlazCutz we can work from DXF, SVG, AI, STL files and sketches / technical drawings. Items can also be designed to work with your existing products and components integrating the latest technology & manufacturing processes by Hypertherm.

We can CNC Plasma cut Mild Steel from 2mm up to 20mm and stock all thicknesses. Specific grades can be obtained quickly to ensure you get what you require.

We can work up to our maximum table cutting dimensions of 1250mm x 1250mm, larger parts can be spliced together. Items can also be CNC machined for clean holes, threads, chamfers and pockets ect..

Single items or bulk work welcome.

We can CNC Plasma cut Mild Steel from 2mm up to 20mm and stock all thicknesses. Specific grades can be obtained quickly to ensure you get what you require.

We can work up to our maximum table cutting dimensions of 1250mm x 1250mm, larger parts can be spliced together. Items can also be CNC machined for clean holes, threads, chamfers and pockets ect..

Single items or bulk work welcome.

Perfect for Flanges, Manifold Plates, Spacers & Construction Fabrications

Get a free quote

Contact Us

Contact us to discuss your requirements.

CNC Plasma Cutting is a great way to create your concept prototype items, plate work or profiles for industrial applications.